Biomaterials Translational ›› 2023, Vol. 4 ›› Issue (3): 151-165.doi: 10.12336/biomatertransl.2023.03.004

• REVIEW • Previous Articles Next Articles

Mugilan Thanigachalam*,#( ), Aezhisai Vallavi Muthusamy Subramanian#

), Aezhisai Vallavi Muthusamy Subramanian#

Received:2023-06-30

Revised:2023-08-07

Accepted:2023-09-08

Online:2023-09-28

Published:2023-09-28

Contact:

*Mugilan Thanigachalam,

Thanigachalam, M.; Subramanian, A. V. M. Fabrication, microstructure and properties of advanced ceramic-reinforced composites for dental implants: a review. Biomater Transl. 2023, 4(3), 151-165.

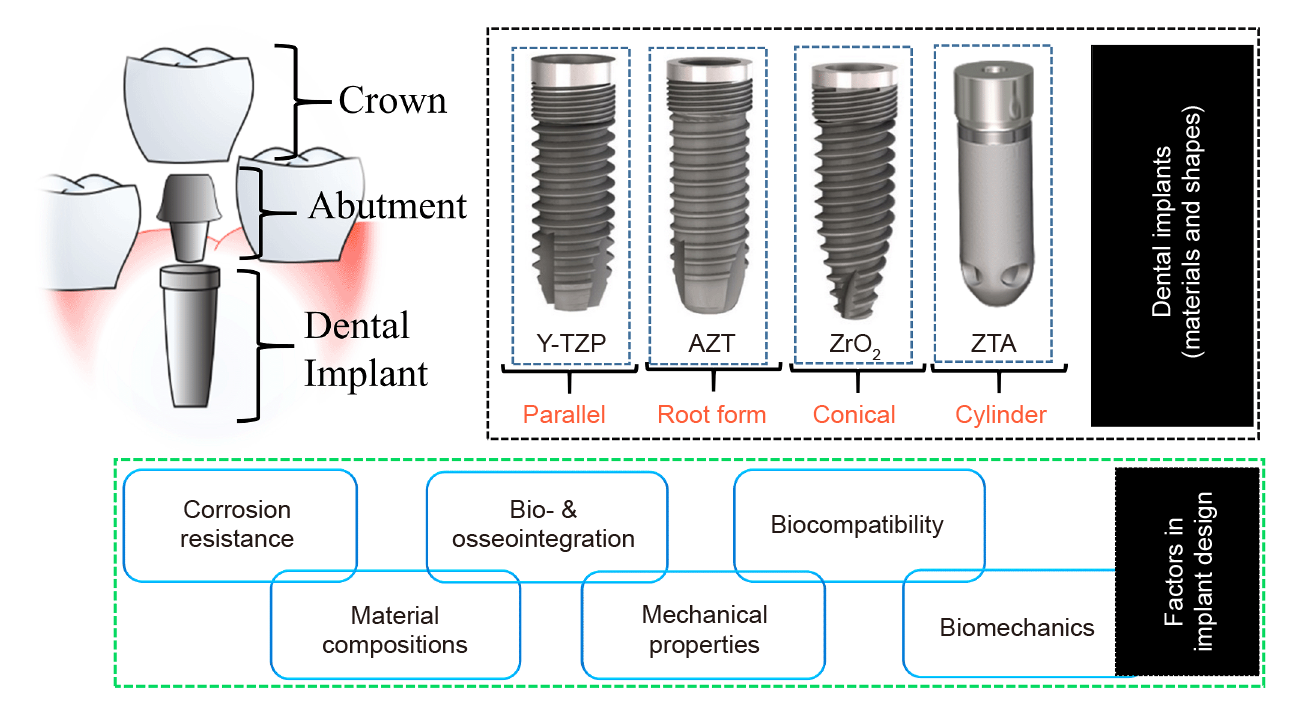

Figure 1. Materials and factors considered in the design of dental implants. AZT: alumina–toughened zirconia; Y–TZP: yttria–stabilised tetragonal zirconia polycrystalline; ZrO2: zirconium dioxide; ZTA: zirconia–toughened alumina.

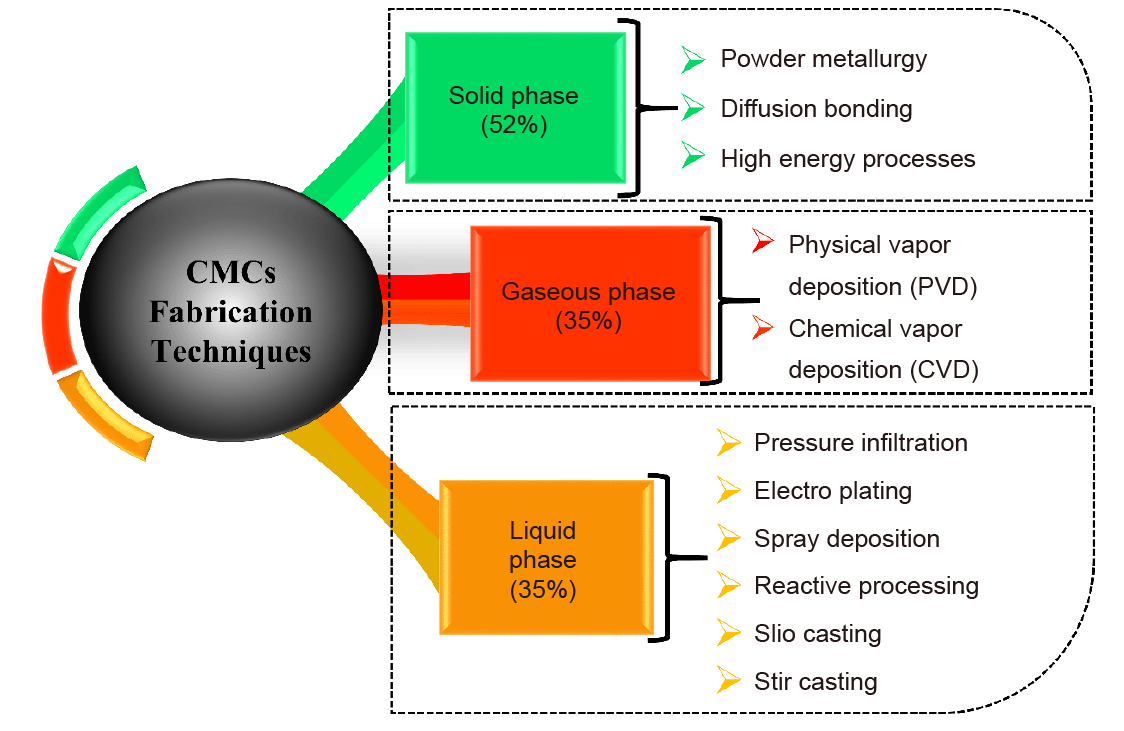

Figure 2. Ceramic matrix composite fabrication processes. CMCs: ceramic matrix composites; CVD: chemical vapour deposition; PVD: physical vapour deposition.

| Implant material | Product name | Manufacturer |

|---|---|---|

| Alumina–toughened zirconia | ZERAMEX (P)lus | Dental point AG, Spreitenbach, Switzerland |

| FairWhiteTM | Fair implant, Schleswig–Holstein, Germany | |

| SDS – Swiss Dental Solutions 1.0 DT | SDS Swiss Dental Solutions AG, Kreuzlingen, Switzerland | |

| Yttria–stabilised tetragonal zirconia polycrystalline | CeraRoot | CeraRoot S.L, Barcelona, Spain |

| Ceralog | Camlog System, Basel, Switzerland | |

| SDS 2.2 | SDS AG, Kreuzlingen, Switzerland | |

| ICX–White | MKI GmbH &Co.KG, Stuttgart, Germany | |

| REPLICATETM System | Natural Dental Implant AG, Berlin, Germany | |

| Zirconia oxide | Konus K3Pro ZirKon Implant system | Argon Medical Productions, Plano, TX, USA |

| Easy Kon | General Implants, Wurmlingen, Germany | |

| Whitesky | Bredent medical, Senden, Germany | |

| CeraRoot | ||

| (S)andard ZV3 | ZV3–ZirconVison GmbH, Munchen, Germany | |

| Ceramic implant | VITA Zahnfabrik, Wurttemberg, Germany |

Table 1. Implant manufacturers and zirconia implant materials

| Implant material | Product name | Manufacturer |

|---|---|---|

| Alumina–toughened zirconia | ZERAMEX (P)lus | Dental point AG, Spreitenbach, Switzerland |

| FairWhiteTM | Fair implant, Schleswig–Holstein, Germany | |

| SDS – Swiss Dental Solutions 1.0 DT | SDS Swiss Dental Solutions AG, Kreuzlingen, Switzerland | |

| Yttria–stabilised tetragonal zirconia polycrystalline | CeraRoot | CeraRoot S.L, Barcelona, Spain |

| Ceralog | Camlog System, Basel, Switzerland | |

| SDS 2.2 | SDS AG, Kreuzlingen, Switzerland | |

| ICX–White | MKI GmbH &Co.KG, Stuttgart, Germany | |

| REPLICATETM System | Natural Dental Implant AG, Berlin, Germany | |

| Zirconia oxide | Konus K3Pro ZirKon Implant system | Argon Medical Productions, Plano, TX, USA |

| Easy Kon | General Implants, Wurmlingen, Germany | |

| Whitesky | Bredent medical, Senden, Germany | |

| CeraRoot | ||

| (S)andard ZV3 | ZV3–ZirconVison GmbH, Munchen, Germany | |

| Ceramic implant | VITA Zahnfabrik, Wurttemberg, Germany |

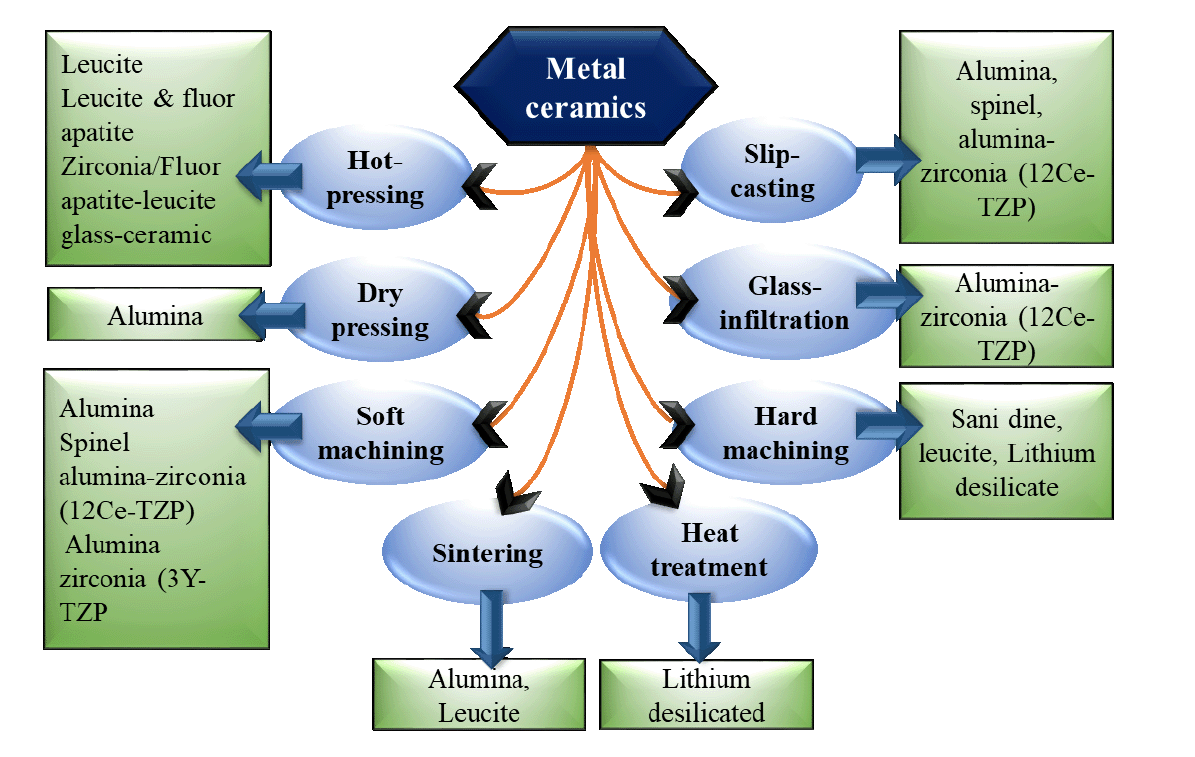

Figure 4. Appropriate fabrication techniques for various crystalline phases. 12Ce–TZP: 12 ceria stabilized tetragonal zirconia polycrystals; 3Y–TZP: 3 yttriastabilised tetragonal zirconia polycrystalline.

| Sintering method | Sintering temperature (°C) | Holding time (minutes) | Relative density (%) | Grain size (nm) | Codesa | |

|---|---|---|---|---|---|---|

| Zirconia | Alumina | |||||

| Microwave sintering (MW) | 1200 | 10 | 98.5 | 210±64 | 270±84 | MW120010 |

| 1200 | 30 | 99 | 240±67 | 300±100 | MW120030 | |

| 1300 | 10 | 99.8 | 280±75 | 400±157 | MW130010 | |

| 1300 | 30 | 99.8 | 280±70 | 380±146 | MW130030 | |

| Conventional sintering (CS) | 1400 | 120 | 98.3 | 240±41 | 350±98 | CS1400120 |

| 1500 | 120 | 99.2 | 330±56 | 450±100 | CS1500120 | |

Table 2. Summary of the sintering process of alumina–toughened zirconia

| Sintering method | Sintering temperature (°C) | Holding time (minutes) | Relative density (%) | Grain size (nm) | Codesa | |

|---|---|---|---|---|---|---|

| Zirconia | Alumina | |||||

| Microwave sintering (MW) | 1200 | 10 | 98.5 | 210±64 | 270±84 | MW120010 |

| 1200 | 30 | 99 | 240±67 | 300±100 | MW120030 | |

| 1300 | 10 | 99.8 | 280±75 | 400±157 | MW130010 | |

| 1300 | 30 | 99.8 | 280±70 | 380±146 | MW130030 | |

| Conventional sintering (CS) | 1400 | 120 | 98.3 | 240±41 | 350±98 | CS1400120 |

| 1500 | 120 | 99.2 | 330±56 | 450±100 | CS1500120 | |

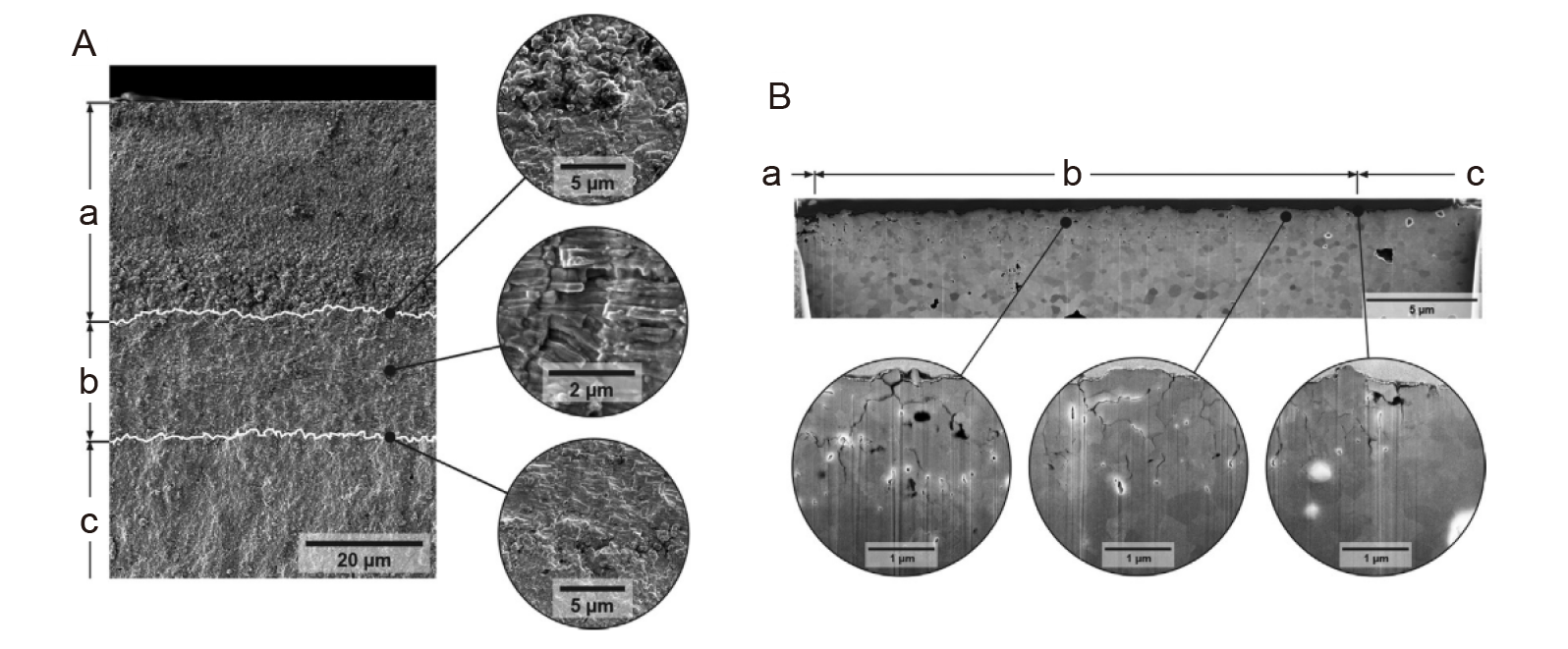

Figure 6. (A) Fracture surface, where three different regions are distinguished: notch (a), micro–cracked area (b), and regular fracture surface (c). (B) The cross–sectional view obtained by focused ion beam analysis of the fracture surface. Reprinted from Turon–Vinas and Anglada.38 Copyright 2018 The Academy of Dental Materials.

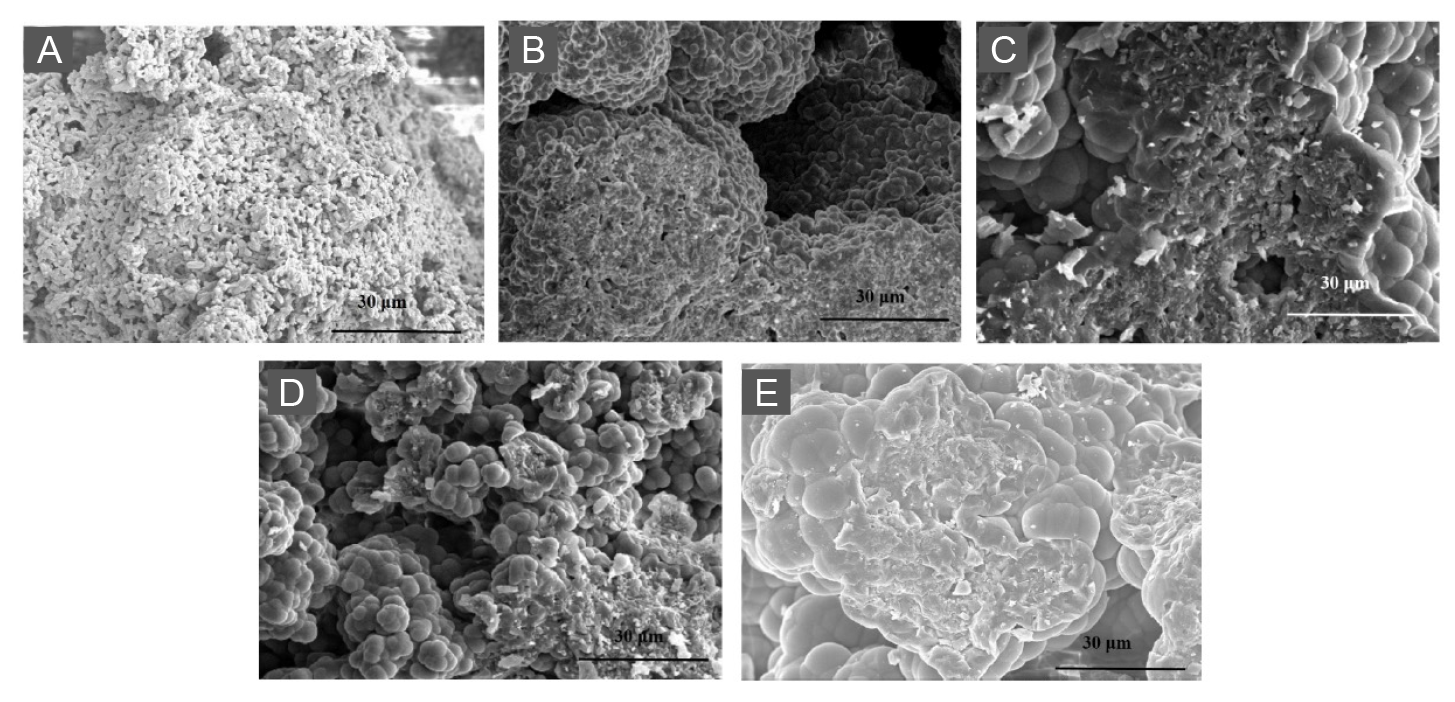

Figure 7. Fracture morphologies of porous Si3N4–Si3N4 composite ceramics as a function of deposition time: (A) 0, (B) 3, (C) 6, (D) 9, and (E) 12 hours. Scale bars: 30 μm. Si3N4: silicon nitride. Reprinted from Cheng et al.43

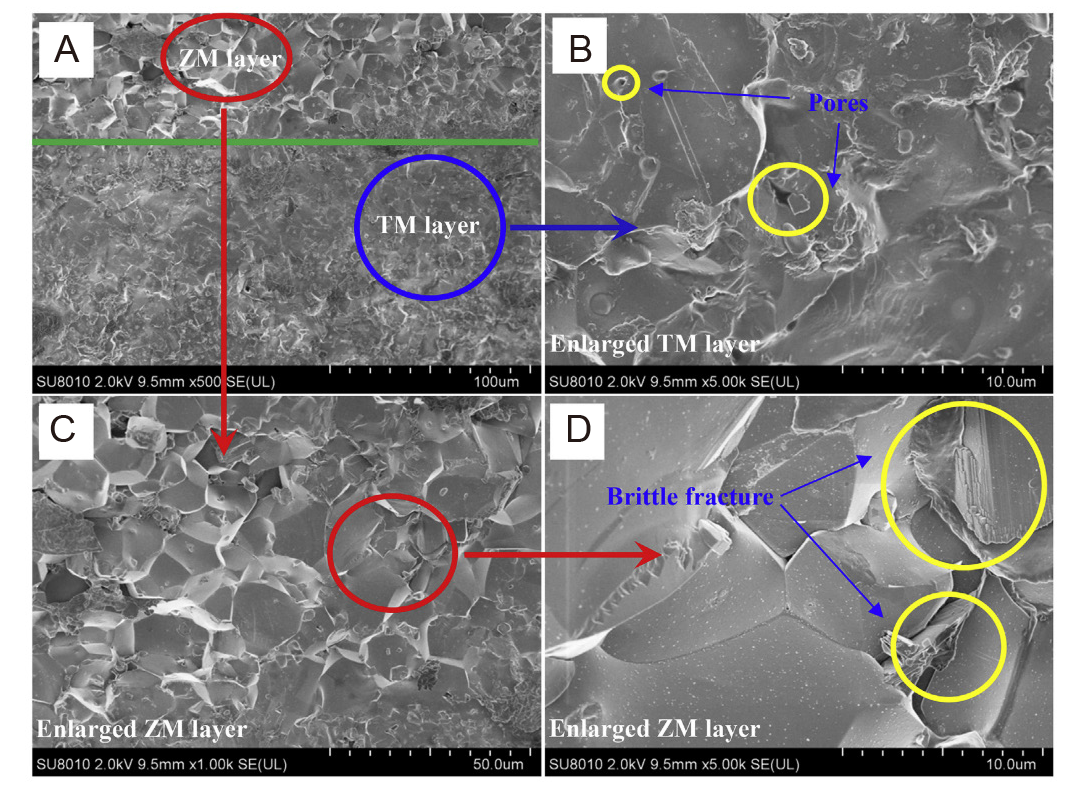

Figure 8. Scanning electron microscopic images of fracture surfaces. Scale bars: 100 μm (A), 10 μm (B, D), 50 μm (C). Reprinted from Liu et al.4 Copyright 2019 Elsevier Ltd and Techna Group S.r.l.

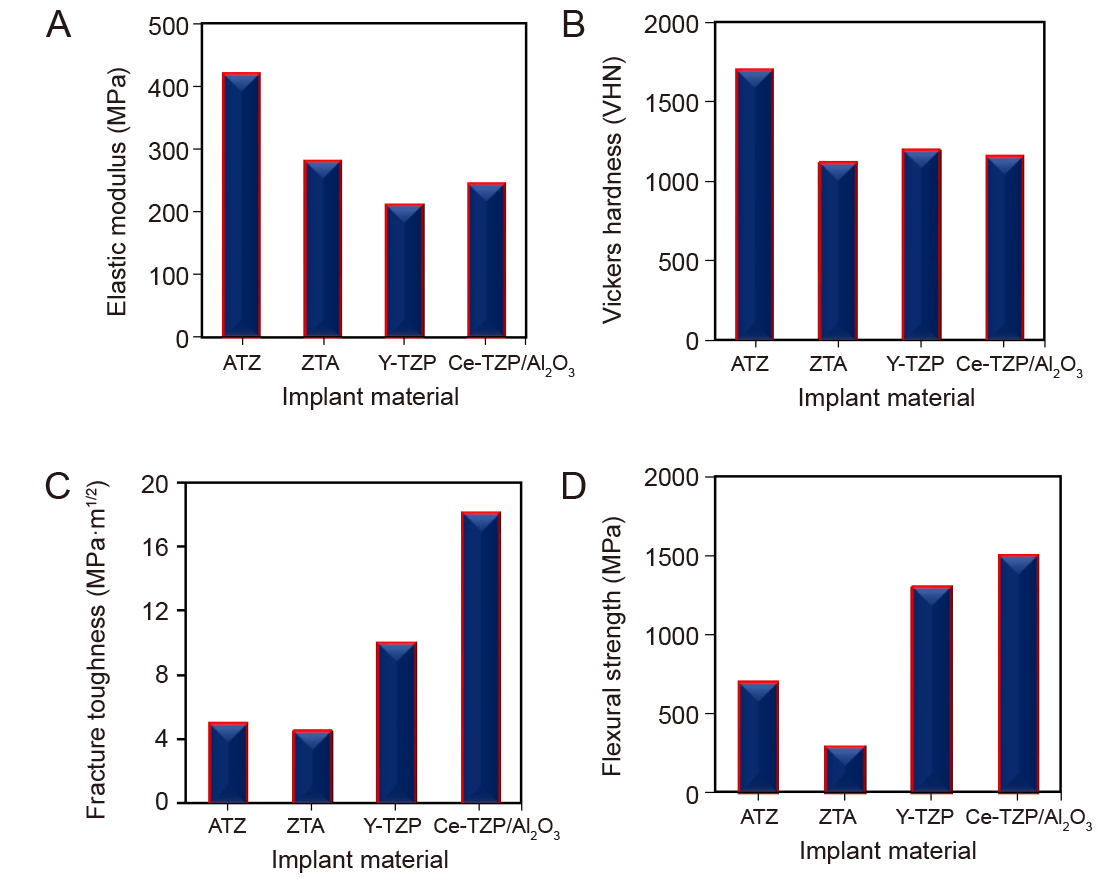

Figure 14. Mechanical properties of different implant materials. (A) Elastic modulus. (B) Vickers hardness. (C) Fracture toughness. (D) Flexural strength. Al2O3: aluminium dioxide; AZT: alumina toughened zirconia; TPZ: tetragonal phase zirconia; Y–TZP: Yttria–stabilised tetragonal zirconia polycrystalline; ZTA: zirconia toughened alumina.

| Studies | Ceramic composites | Method of mixing | Conditions for sintering | Results |

|---|---|---|---|---|

| Liu et al. | Al2O3–ZrB2–MgO/Al2O3–TiN–MgO | Planetary ball milling machine, alumina ball to powder ratio 1:3 | Hot pressed, vacuum at 1650°C, 60 minutes under 35 MPa. | Flexural strength = 654 ± 43 MPa, fracture toughness = 8.7 ± 0.2 MPa·m1/2, Vickers hardness = 20.1 ± 0.5 GPa, elastic modulus = 351 GPa |

| Tovar–Vargas et al. | Yttrium doped ZrO2–Al2O3 composite powders with partially stabilised ZrO2 (PSZ) | Wet ball milling | Pressing (370 MPa); Sintering (1600°C/5 hours) | Highest Kc ~8.40 ± 0.4 MPa and hardness ~16.31 ± 0.58 GPa were obtained for the 30 wt% PSZ–Al2O3 |

| Smirnov et al. | Hierarchical tantalum–graphene flakes reinforced zirconia | Ball milling | Spark plasma sintering (maximum temperatures of 1400 and 1500°C under vacuum at a heating rate of 100°C/min, and applied pressure of 80 MPa) | Flexural strength 30% increment and toughness 175% increase compared to monolithic Zr |

| Liu et al. | ρ–Al2O3 | Wet–milled with a rotating speed of 300 r/min for 3 hours | Compacted at 10 MPa, sintered at a heating rate of 5°C/min to 1600°C, 3 hours | Hot modulus of rupture = 6.26 MPa, thermal shock resistance = 2.53 |

| Yan et al. | ZrB2–SiC–Ni | Ball–milled for 12 hours | Spark plasma sintering | Fracture toughness = 8.3 MPa, |

| Smirnov et al. | 3Y–TZP/Ta | High–energy ball milling | spark plasma sintering, vacuum (≈ 1 × 102 Mbar) at 1400°C, 200°C/min | Flexural strength = 967 MPa, surface roughness Ra = 0.3 ± 0.1 |

| Prajzler et al. | Alumina based zirconia ceramics | Ball milling | Pressureless rapid rate sintering (100°C/min to 1500°C/min) | Nearly total density (> 95% TD) without forming cracks or other structural defects. |

| Ke et al. | WcoB–TiC | Planetary ball milling machine | Sintering at 1500°C, 60 minutes | Hardness = 91.6 HRA, transverse rapture strength = 1783 MPa. |

| Cheng et al. | Porous Si3N4–Si3N4 | Ball milling | Sintering and 3D printing combined with low–pressure chemical vapour infiltration | Density increased from 0.99 to 2.02 g/cm3 flexural strength of 47 ± 2 MPa |

| Manshor et al. | TiO2 (ZTA–TiO2) Cr2O3 | Ball milling | Sintering 1600°C for 1 hour with 5°C/min | Fracture toughness increased to 7.15 MPa·m1/2 by adding up to 0.6 wt% Cr2O3 |

| Zhu et al. | MgTiO3/CaO–B2O3–SiO2 | Ball milling with ethyl alcohol for 300 minutes | Sintered at 810°C, 120 minutes | Bulk density = 3.1270 g/cm3, flexural strength = 214.85 MPa |

| Wang et al. | Al2O3/TiC | Hybrid slurries form ball–milling for 60 hours | Hot–pressing sintering 1700–1750°C in a nitrogen atmosphere, 35 MPa | Fracture toughness = 97 MPa·m1/2, Vickers hardness = 37 GPa |

| Zhang et al. | SiAlON–Si3N4 | Ball milling | Reaction–bonded sintering, 4°C/min to 1500°C | Compressive strength = 185 MPa |

| Zhao et al. | ZrB2–SiC–Ni | Ball–milled for 12 hours using ZrO2 ball media | Spark plasma sintering, 1400°C for 1 minute, 200°C/min | Hardness = 20.2 GPa, elastic modulus of ZS =53.7 GPa |

| Li et al. | CM2A8 (CaMg2Al16O27) and C2M2A14 (Ca2Mg2Al28O46) | Calcinated at 900°C for 1 hour | Hot press sintering 1750°C, 15 MPa. | Vickers hardness = 12.95 GPa, fracture toughness = 2.17 MPa, flexural strength = 248 MPa |

Table 3. Systematic literature collection of results from recent research

| Studies | Ceramic composites | Method of mixing | Conditions for sintering | Results |

|---|---|---|---|---|

| Liu et al. | Al2O3–ZrB2–MgO/Al2O3–TiN–MgO | Planetary ball milling machine, alumina ball to powder ratio 1:3 | Hot pressed, vacuum at 1650°C, 60 minutes under 35 MPa. | Flexural strength = 654 ± 43 MPa, fracture toughness = 8.7 ± 0.2 MPa·m1/2, Vickers hardness = 20.1 ± 0.5 GPa, elastic modulus = 351 GPa |

| Tovar–Vargas et al. | Yttrium doped ZrO2–Al2O3 composite powders with partially stabilised ZrO2 (PSZ) | Wet ball milling | Pressing (370 MPa); Sintering (1600°C/5 hours) | Highest Kc ~8.40 ± 0.4 MPa and hardness ~16.31 ± 0.58 GPa were obtained for the 30 wt% PSZ–Al2O3 |

| Smirnov et al. | Hierarchical tantalum–graphene flakes reinforced zirconia | Ball milling | Spark plasma sintering (maximum temperatures of 1400 and 1500°C under vacuum at a heating rate of 100°C/min, and applied pressure of 80 MPa) | Flexural strength 30% increment and toughness 175% increase compared to monolithic Zr |

| Liu et al. | ρ–Al2O3 | Wet–milled with a rotating speed of 300 r/min for 3 hours | Compacted at 10 MPa, sintered at a heating rate of 5°C/min to 1600°C, 3 hours | Hot modulus of rupture = 6.26 MPa, thermal shock resistance = 2.53 |

| Yan et al. | ZrB2–SiC–Ni | Ball–milled for 12 hours | Spark plasma sintering | Fracture toughness = 8.3 MPa, |

| Smirnov et al. | 3Y–TZP/Ta | High–energy ball milling | spark plasma sintering, vacuum (≈ 1 × 102 Mbar) at 1400°C, 200°C/min | Flexural strength = 967 MPa, surface roughness Ra = 0.3 ± 0.1 |

| Prajzler et al. | Alumina based zirconia ceramics | Ball milling | Pressureless rapid rate sintering (100°C/min to 1500°C/min) | Nearly total density (> 95% TD) without forming cracks or other structural defects. |

| Ke et al. | WcoB–TiC | Planetary ball milling machine | Sintering at 1500°C, 60 minutes | Hardness = 91.6 HRA, transverse rapture strength = 1783 MPa. |

| Cheng et al. | Porous Si3N4–Si3N4 | Ball milling | Sintering and 3D printing combined with low–pressure chemical vapour infiltration | Density increased from 0.99 to 2.02 g/cm3 flexural strength of 47 ± 2 MPa |

| Manshor et al. | TiO2 (ZTA–TiO2) Cr2O3 | Ball milling | Sintering 1600°C for 1 hour with 5°C/min | Fracture toughness increased to 7.15 MPa·m1/2 by adding up to 0.6 wt% Cr2O3 |

| Zhu et al. | MgTiO3/CaO–B2O3–SiO2 | Ball milling with ethyl alcohol for 300 minutes | Sintered at 810°C, 120 minutes | Bulk density = 3.1270 g/cm3, flexural strength = 214.85 MPa |

| Wang et al. | Al2O3/TiC | Hybrid slurries form ball–milling for 60 hours | Hot–pressing sintering 1700–1750°C in a nitrogen atmosphere, 35 MPa | Fracture toughness = 97 MPa·m1/2, Vickers hardness = 37 GPa |

| Zhang et al. | SiAlON–Si3N4 | Ball milling | Reaction–bonded sintering, 4°C/min to 1500°C | Compressive strength = 185 MPa |

| Zhao et al. | ZrB2–SiC–Ni | Ball–milled for 12 hours using ZrO2 ball media | Spark plasma sintering, 1400°C for 1 minute, 200°C/min | Hardness = 20.2 GPa, elastic modulus of ZS =53.7 GPa |

| Li et al. | CM2A8 (CaMg2Al16O27) and C2M2A14 (Ca2Mg2Al28O46) | Calcinated at 900°C for 1 hour | Hot press sintering 1750°C, 15 MPa. | Vickers hardness = 12.95 GPa, fracture toughness = 2.17 MPa, flexural strength = 248 MPa |

| 1. |

Wójcik, N. A.; Tagiara, N. S.; Möncke, D.; Kamitsos, E. I.; Ali, S.; Ryl, J.; Barczyński, R. J. Mechanism of hopping conduction in Be-Fe-Al-Te-O semiconducting glasses and glass-ceramics. J Mater Sci. 2022, 57, 1633-1647.

doi: 10.1007/s10853-021-06834-w |

| 2. |

Magnani, G.; Fabbri, P.; Leoni, E.; Salernitano, E.; Mazzanti, F. New perspectives on zirconia composites as biomaterials. J Compos Sci. 2021, 5, 244.

doi: 10.3390/jcs5090244 URL |

| 3. | Taeh, A. S.; Othman, F. M.; Abdul-Hamead, A. A. Reviewing alumina-zirconia composite as a ceramic biomaterial. Hunan Daxue Xuebao. 2022, 49, 263-273. |

| 4. |

Liu, C.; Sun, J.; Li, G.; Li, B.; Gong, F. Fabrication, mechanical properties and fracture behaviors of the laminated Al2O3-ZrB2-MgO / Al2O3-TiN-MgO ceramic composite. Ceram Int. 2020, 46, 857-865.

doi: 10.1016/j.ceramint.2019.09.043 URL |

| 5. |

Williams, T.; Yeomans, J.; Smith, P.; Heaton, A.; Hampson, C. Effect of interfacial area on densification and microstructural evolution in silicon carbide-boron carbide particulate composites. J Mater Sci. 2016, 51, 353-361.

doi: 10.1007/s10853-015-9384-3 URL |

| 6. |

Alcudia-Ramos, M. A.; Fuentez-Torres, M. O.; Ortiz-Chi, F.; Espinosa-González, C. G.; Hernández‐Como, N.; García-Zaleta, D. S.; Kesarla, M. K.; Torres-Torres, J. G.; Collins-Martínez, V.; Godavarthi, S. Fabrication of g-C3N4/TiO2 heterojunction composite for enhanced photocatalytic hydrogen production. Ceram Int. 2020, 46, 38-45.

doi: 10.1016/j.ceramint.2019.08.228 URL |

| 7. |

Pradhan, S.; Singh, S.; Prakash, C.; Królczyk, G.; Pramanik, A.; Pruncu, C. I. Investigation of machining characteristics of hard-to-machine Ti-6Al-4V-ELI alloy for biomedical applications. J Mater Res Technol. 2019, 8, 4849-4862.

doi: 10.1016/j.jmrt.2019.08.033 URL |

| 8. |

Saeed, F.; Muhammad, N.; Khan, A. S.; Sharif, F.; Rahim, A.; Ahmad, P.; Irfan, M. Prosthodontics dental materials: From conventional to unconventional. Mater Sci Eng C Mater Biol Appl. 2020, 106, 110167.

doi: 10.1016/j.msec.2019.110167 URL |

| 9. | Lin, C.; Zhao, Q.; Zhao, X.; Yang, Y. Cavitation erosion of metallic materials. Int J Georesources Environment. 2018, 4, 1-8. |

| 10. |

Ramachandran, K.; Boopalan, V.; Bear, J. C.; Subramani, R. Multi-walled carbon nanotubes (MWCNTs)-reinforced ceramic nanocomposites for aerospace applications: a review. J Mater Sci. 2022, 57, 3923-3953.

doi: 10.1007/s10853-021-06760-x |

| 11. |

Meena, K. L.; Vidyasagar, C. S.; Benny Karunakar, D. Mechanical and tribological properties of MgO/multiwalled carbon nanotube-reinforced zirconia-toughened alumina composites developed through spark plasma sintering and microwave sintering. J Mater Eng Perform. 2022, 31, 682-696.

doi: 10.1007/s11665-021-06170-9 |

| 12. |

Condi Mainardi, J.; Bonini Demarchi, C.; Mirdrikvand, M.; Karim, M. N.; Dreher, W.; Rezwan, K.; Maas, M. 3D bioprinting of hydrogel/ceramic composites with hierarchical porosity. J Mater Sci. 2022, 57, 3662-3677.

doi: 10.1007/s10853-021-06829-7 |

| 13. |

Bartoli, M.; Duraccio, D.; Faga, M. G.; Piatti, E.; Torsello, D.; Ghigo, G.; Malucelli, G. Mechanical, electrical, thermal and tribological behavior of epoxy resin composites reinforced with waste hemp-derived carbon fibers. J Mater Sci. 2022, 57, 14861-14876.

doi: 10.1007/s10853-022-07550-9 |

| 14. |

Osman, R. B.; Swain, M. V. A critical review of dental implant materials with an emphasis on titanium versus zirconia. Materials (Basel). 2015, 8, 932-958.

doi: 10.3390/ma8030932 URL |

| 15. | Tartsch, J.; Blatz, M. B. Ceramic dental implants: an overview of materials, characteristics, and application concepts. Compend Contin Educ Dent. 2022, 43, 482-488; quiz 489. |

| 16. |

Thanigachalam, M.; Muthusamy Subramanian, A. V. Evaluation of PEEK-TiO(2)- SiO(2) nanocomposite as biomedical implants with regard to in-vitro biocompatibility and material characterization. J Biomater Sci Polym Ed. 2022, 33, 727-746.

doi: 10.1080/09205063.2021.2014028 URL |

| 17. |

Muthusamy Subramanian, A. V.; Thanigachalam, M. Mechanical performances, in-vitro antibacterial study and bone stress prediction of ceramic particulates filled polyether ether ketone nanocomposites for medical applications. J Polym Res. 2022, 29, 318.

doi: 10.1007/s10965-022-03180-6 |

| 18. | Thanigachalam, M.; Muthusamy Subramanian, A. V. In-vitro cytotoxicity assessment and cell adhesion study of functionalized nTiO2 reinforced PEEK biocompatible polymer composite. Polym Plasts Technol Mater. 2022, 61, 566-576. |

| 19. |

Mugilan, T.; Aezhisai Vallavi, M. S.; Sugumar, D. Materialistic characterization, thermal properties, and cytocompatibility investigations on acrylic acid-functionalized nSiO2-reinforced PEEK polymeric nanocomposite. Colloid Polym Sci. 2022, 300, 1155-1168.

doi: 10.1007/s00396-022-05016-7 |

| 20. |

Zhai, X.; Zhang, X.; Ma, Y.; Liu, J. Influence of Bi2O3, TiO2 additives and sintering process on the performance of ITO target based on normal pressure sintering method. Trans Indian Ceramic Soc. 2019, 78, 83-88.

doi: 10.1080/0371750X.2019.1605935 URL |

| 21. |

Smirnov, A.; Peretyagin, P.; Bartolomé, J. F. Processing and mechanical properties of new hierarchical metal-graphene flakes reinforced ceramic matrix composites. J Eur Ceram Soc. 2019, 39, 3491-3497.

doi: 10.1016/j.jeurceramsoc.2019.02.044 URL |

| 22. |

Qian, K.; Yao, Z.; Lin, H.; Zhou, J.; Haidry, A. A.; Qi, T.; Chen, W.; Guo, X. The influence of Nd substitution in Ni-Zn ferrites for the improved microwave absorption properties. Ceram Int. 2020, 46, 227-235.

doi: 10.1016/j.ceramint.2019.08.255 URL |

| 23. |

Ghosh, R.; Sarkar, R. Comparative analysis of novel calcium phosphate based machinable bioceramic composites. Trans Indian Ceramic Soc. 2020, 79, 131-138.

doi: 10.1080/0371750X.2020.1773931 URL |

| 24. |

Raghavendra, C. R.; Basavarajappa, S.; Sogalad, I.; Naik, K. Study on wear mechanism and contact temperature against dry sliding wear of Ni-Al2O3 nanocomposite coating. Trans Indian Ceramic Soc. 2020, 79, 139-143.

doi: 10.1080/0371750X.2020.1779614 URL |

| 25. |

Yadav, P.; Rattan, S.; Tripathi, A.; Kumar, S. Tailoring of complex permittivity, permeability, and microwave-absorbing properties of CoFe2O4/NG/PMMA nanocomposites through swift heavy ions irradiation. Ceram Int. 2020, 46, 317-324.

doi: 10.1016/j.ceramint.2019.08.265 URL |

| 26. |

Liu, C.; Li, X.; Wu, Y.; Zhang, L.; Chang, X.; Yuan, X.; Wang, X. Fabrication of multilayer porous structured TiO2-ZrTiO4-SiO2heterostructure towards enhanced photo-degradation activities. Ceram Int. 2020, 46, 476-486.

doi: 10.1016/j.ceramint.2019.08.285 URL |

| 27. |

Avcıoğlu, S.; Buldu, M.; Kaya, F.; Üstündağ, C. B.; Kam, E.; Menceloğlu, Y. Z.; Kaptan, H. Y.; Kaya, C. Processing and properties of boron carbide (B4C) reinforced LDPE composites for radiation shielding. Ceram Int. 2020, 46, 343-352.

doi: 10.1016/j.ceramint.2019.08.268 URL |

| 28. |

Zhang, H.; Li, M.; Zhu, C.; Tang, Q.; Kang, P.; Cao, J. Preparation of magnetic α-Fe2O3/ZnFe2O4@Ti3C2 MXene with excellent photocatalytic performance. Ceram Int. 2020, 46, 81-88.

doi: 10.1016/j.ceramint.2019.08.236 URL |

| 29. |

Zhang, Z.; Lin, T.; Shao, H.; Peng, J.; Wang, A.; Zhang, Y.; Yu, X.; Liu, S.; Wang, L.; Zhao, M. Effect of different dopants on porous calcium silicate composite bone scaffolds by 3D gel-printing. Ceram Int. 2020, 46, 325-330.

doi: 10.1016/j.ceramint.2019.08.266 URL |

| 30. |

Song, S.; Gao, Z.; Lu, B.; Bao, C.; Zheng, B.; Wang, L. Performance optimization of complicated structural SiC/Si composite ceramics prepared by selective laser sintering. Ceram Int. 2020, 46, 568-575.

doi: 10.1016/j.ceramint.2019.09.004 URL |

| 31. |

Su, N. K.; Rejab, N. A.; Ahmad, Z. A.; Abdullah, N. S. Densification of zirconia toughened alumina added CeO2 ceramics via hot isostatic press sintering technique. Key Eng Mater. 2022, 908, 228-233.

doi: 10.4028/v-55iy3h URL |

| 32. |

Thankachan, T.; Soorya Prakash, K.; Malini, R.; Ramu, S.; Sundararaj, P.; Rajandran, S.; Rammasamy, D.; Jothi, S. Prediction of surface roughness and material removal rate in wire electrical discharge machining on aluminum based alloys/composites using Taguchi coupled Grey Relational Analysis and Artificial Neural Networks. Appl Surf Sci. 2019, 472, 22-35.

doi: 10.1016/j.apsusc.2018.06.117 URL |

| 33. |

Adibpur, F.; Tayebifard, S. A.; Zakeri, M.; Shahedi Asl, M. Spark plasma sintering of quadruplet ZrB2-SiC-ZrC-Cf composites. Ceram Int. 2020, 46, 156-164.

doi: 10.1016/j.ceramint.2019.08.243 URL |

| 34. |

Gil-Flores, L.; Salvador, M. D.; Penaranda-Foix, F. L.; Dalmau, A.; Fernández, A.; Borrell, A. Tribological and wear behaviour of alumina toughened zirconia nanocomposites obtained by pressureless rapid microwave sintering. J Mech Behav Biomed Mater. 2020, 101, 103415.

doi: 10.1016/j.jmbbm.2019.103415 URL |

| 35. |

Xia, Y.; Mou, J.; Deng, G.; Wan, S.; Tieu, K.; Zhu, H.; Xue, Q. Sintered ZrO2-TiO2 ceramic composite and its mechanical appraisal. Ceram Int. 2020, 46, 775-785.

doi: 10.1016/j.ceramint.2019.09.032 URL |

| 36. |

Yan, X.; Jin, X.; Li, P.; Hou, C.; Hao, X.; Li, Z.; Fan, X. Microstructures and mechanical properties of ZrB2-SiC-Ni ceramic composites prepared by spark plasma sintering. Ceram Int. 2019, 45, 16707-16712.

doi: 10.1016/j.ceramint.2019.05.151 URL |

| 37. |

Cui, E.; Zhao, J.; Wang, X. Determination of microstructure and mechanical properties of graphene reinforced Al2O3-Ti(C, N) ceramic composites. Ceram Int. 2019, 45, 20593-20599.

doi: 10.1016/j.ceramint.2019.07.041 URL |

| 38. |

Turon-Vinas, M.; Anglada, M. Strength and fracture toughness of zirconia dental ceramics. Dent Mater. 2018, 34, 365-375.

doi: 10.1016/j.dental.2017.12.007 URL |

| 39. |

Smirnov, A.; Peretyagin, P.; Bartolomé, J. F. Wire electrical discharge machining of 3Y-TZP/Ta ceramic-metal composites. J Alloys Compd. 2018, 739, 62-68.

doi: 10.1016/j.jallcom.2017.12.221 URL |

| 40. |

Prajzler, V.; Salamon, D.; Maca, K. Pressure-less rapid rate sintering of pre-sintered alumina and zirconia ceramics. Ceram Int. 2018, 44, 10840-10846.

doi: 10.1016/j.ceramint.2018.03.132 URL |

| 41. |

Ke, D.; Pan, Y.; Wu, R.; Xu, Y.; Wang, P.; Wu, T. Effect of initial Co content on the microstructure, mechanical properties and high-temperature oxidation resistance of WCoB-TiC ceramic composites. Ceram Int. 2018, 44, 1213-1219.

doi: 10.1016/j.ceramint.2017.10.046 URL |

| 42. |

Rakshit, R.; Das, A. K. A review on cutting of industrial ceramic materials. Precis Eng. 2019, 59, 90-109.

doi: 10.1016/j.precisioneng.2019.05.009 URL |

| 43. |

Cheng, Z.; Ye, F.; Liu, Y.; Qiao, T.; Li, J.; Qin, H.; Cheng, L.; Zhang, L. Mechanical and dielectric properties of porous and wave-transparent Si3N4-Si3N4 composite ceramics fabricated by 3D printing combined with chemical vapor infiltration. J Adv Ceram. 2019, 8, 399-407.

doi: 10.1007/s40145-019-0322-8 |

| 44. | Srinivasan, V. P.; Palani, P. K.; Selvarajan, L. Experimental investigation on electrical discharge machining of ceramic composites (Si3N4-TiN) using RSM. Int J Comput Mater Sci Surf Eng. 2018, 7, 104-115. |

| 45. |

Kuntz, M.; Krüger, R. The effect of microstructure and chromia content on the properties of zirconia toughened alumina. Ceram Int. 2018, 44, 2011-2020.

doi: 10.1016/j.ceramint.2017.10.146 URL |

| 46. |

Monzavi, M.; Zhang, F.; Meille, S.; Douillard, T.; Adrien, J.; Noumbissi, S.; Nowzari, H.; Chevalier, J. Influence of artificial aging on mechanical properties of commercially and non-commercially available zirconia dental implants. J Mech Behav Biomed Mater. 2020, 101, 103423.

doi: 10.1016/j.jmbbm.2019.103423 URL |

| 47. |

Gao, P. Z.; Cheng, L.; Yuan, Z.; Liu, X.-p.; Xiao, H.-n. High temperature mechanical retention characteristics and oxidation behaviors of the MoSi2(Cr5Si3)—RSiC composites prepared via a PIP—AAMI combined process. J Adv Ceram. 2019, 8, 196-208.

doi: 10.1007/s40145-018-0305-1 |

| 48. | Machaka, R.; Derry, T. E.; Sigalas, I.; Herrmann, M. Analysis of the Indentation Size Effect in the Microhardness Measurements in B6O. Adv Mater Sci Eng. 2011, 2011, 539252. |

| 49. |

Singaravel Chidambara Nathan, A.; Tah, R.; Balasubramanium, M. K. Evaluation of fracture toughness of zirconia silica nano-fibres reinforced feldespathic ceramic. J Oral Biol Craniofac Res. 2018, 8, 221-224.

doi: 10.1016/j.jobcr.2017.09.003 URL |

| 50. |

Liao, Y.; Wang, Y.; Chen, Z.; Wang, X.; Li, J.; Guo, R.; Liu, C.; Gan, G.; Wang, G.; Li, Y.; Zhang, H. Microstructure and enhanced magnetic properties of low-temperature sintered LiZnTiMn ferrite ceramics with Bi2O3-Al2O3 additive. Ceram Int. 2020, 46, 487-492.

doi: 10.1016/j.ceramint.2019.08.286 URL |

| 51. |

Talimian, A.; Galusek, D. Aqueous slip casting of translucent magnesium aluminate spinel: Effects of dispersant concentration and solid loading. Ceram Int. 2019, 45, 10646-10653.

doi: 10.1016/j.ceramint.2019.02.134 URL |

| 52. |

Hou, P. J.; Guo, Y. F.; Sun, L. X.; Deng, G. Q. Simulation of temperature and thermal stress filed during reciprocating traveling WEDM of insulating ceramics. Procedia CIRP. 2013, 6, 410-415.

doi: 10.1016/j.procir.2013.03.010 URL |

| 53. |

Caravaca, C. F.; Flamant, Q.; Anglada, M.; Gremillard, L.; Chevalier, J. Impact of sandblasting on the mechanical properties and aging resistance of alumina and zirconia based ceramics. J Eur Ceram Soc. 2018, 38, 915-925.

doi: 10.1016/j.jeurceramsoc.2017.10.050 URL |

| 54. |

Jindal, P. C. A new method for evaluating the indentation toughness of hardmetals. Crystals. 2018, 8, 197.

doi: 10.3390/cryst8050197 URL |

| 55. |

Ahmad, I.; Islam, M.; Al Habis, N.; Parvez, S. Hot-pressed graphene nanoplatelets or/and zirconia reinforced hybrid alumina nanocomposites with improved toughness and mechanical characteristics. J Mater Sci Technol. 2020, 40, 135-145.

doi: 10.1016/j.jmst.2019.08.048 URL |

| 56. |

Chen, X.; Liu, C.; Zheng, W.; Han, J.; Zhang, L.; Liu, C. High strength silica-based ceramics material for investment casting applications: Effects of adding nanosized alumina coatings. Ceram Int. 2020, 46, 196-203.

doi: 10.1016/j.ceramint.2019.08.248 URL |

| 57. |

Yu, H.; Hou, Z.; Guo, X.; Chen, Y.; Li, J.; Luo, L.; Li, J.; Yang, T. Finite element analysis on flexural strength of Al2O3-ZrO2 composite ceramics with different proportions. Mater Sci Eng A. 2018, 738, 213-218.

doi: 10.1016/j.msea.2018.05.075 URL |

| 58. |

Rao, P. K.; Jana, P.; Ahmad, M. I.; Roy, P. K. Synthesis and characterization of zirconia toughened alumina ceramics prepared by co-precipitation method. Ceram Int. 2019, 45, 16054-16061.

doi: 10.1016/j.ceramint.2019.05.121 URL |

| 59. |

Tovar-Vargas, D.; Roitero, E.; Anglada, M.; Jiménez-Piqué, E.; Reveron, H. Mechanical properties of ceria-calcia stabilized zirconia ceramics with alumina additions. J Eur Ceram Soc. 2021, 41, 5602-5612.

doi: 10.1016/j.jeurceramsoc.2021.05.006 URL |

| 60. |

Liu, J.; Huo, W.; Zhang, X.; Ren, B.; Li, Y.; Zhang, Z.; Yang, J. Optimal design on the high-temperature mechanical properties of porous alumina ceramics based on fractal dimension analysis. J Adv Ceram. 2018, 7, 89-98.

doi: 10.1007/s40145-018-0260-x |

| 61. |

Manshor, H.; Azhar, A. Z. A.; Rashid, R. A.; Sulaiman, S.; Abdullah, E. C.; Ahmad, Z. A. Effects of Cr2O3 addition on the phase, mechanical properties, and microstructure of zirconia-toughened alumina added with TiO2 (ZTA-TiO2) ceramic composite. Int J Refract Met Hard Mater. 2016, 61, 40-45.

doi: 10.1016/j.ijrmhm.2016.08.005 URL |

| 62. |

Zhu, X.; Kong, F.; Ma, X. Sintering behavior and properties of MgTiO3/CaO-B2O3-SiO2 ceramic composites for LTCC applications. Ceram Int. 2019, 45, 1940-1945.

doi: 10.1016/j.ceramint.2018.10.086 URL |

| 63. |

Wang, X.; Zhao, J.; Cui, E.; Song, S.; Liu, H.; Song, W. Microstructure, mechanical properties and toughening mechanisms of graphene reinforced Al2O3-WC-TiC composite ceramic tool material. Ceram Int. 2019, 45, 10321-10329.

doi: 10.1016/j.ceramint.2019.02.087 URL |

| 64. |

Zhang, L.; Liu, X.; Li, M.; Xu, E.; Zhao, F.; Yuan, H.; Sun, X.; Zhang, C.; Gao, L.; Gao, J. Feasibility of SiAlON-Si3N4 composite ceramic as a potential bone repairing material. Ceram Int. 2020, 46, 1760-1765.

doi: 10.1016/j.ceramint.2019.09.150 URL |

| 65. |

Zhao, H.; Li, Z.; Zhang, M.; Li, J.; Wu, M.; Li, X.; Chen, J.; Xie, M.; Li, J.; Sun, X. High-performance Al2O3-YAG:Ce composite ceramic phosphors for miniaturization of high-brightness white light-emitting diodes. Ceram Int. 2020, 46, 653-662.

doi: 10.1016/j.ceramint.2019.09.017 URL |

| 66. |

Li, B.; Li, G.; Chen, H.; Chen, J.; Hou, X.; Li, Y. Physical and mechanical properties of hot-press sintering ternary CM2A8 (CaMg2Al16O27) and C2M2A14 (Ca2Mg2Al28O46) ceramics. J Adv Ceram. 2018, 7, 229-236.

doi: 10.1007/s40145-018-0274-4 |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||