Biomaterials Translational ›› 2022, Vol. 3 ›› Issue (2): 142-151.doi: 10.12336/biomatertransl.2022.02.006

• RESEARCH ARTICLE • Previous Articles Next Articles

Seyed Ataollah Naghavi1, Changning Sun2, Mahbubeh Hejazi3, Maryam Tamaddon1, Jibao Zheng2, Leilei Wang2, Chenrui Zhang2, Swastina Nath Varma1, Dichen Li2, Mehran Moazen3, Ling Wang2,*( ), Chaozong Liu1,*(

), Chaozong Liu1,*( )

)

Received:2022-05-04

Revised:2022-06-02

Accepted:2022-06-09

Online:2022-06-28

Published:2022-06-28

Contact:

Ling Wang,Chaozong Liu

E-mail:menlwang@mail.xjtu.edu.cn;chaozong.liu@ucl.ac.uk

About author:Chaozong Liu, chaozong.liu@ucl.ac.uk.Naghavi, S. A.; Sun, C.; Hejazi, M.; Tamaddon, M.; Zheng, J.; Wang, L.; Zhang, C.; Varma, S. N.; Li, D.; Moazen, D.; Wang, L.; Liu, C. On the mechanical aspect of additive manufactured polyether-ether-ketone scaffold for repair of large bone defects. Biomater Transl. 2022, 3(2), 142-151.

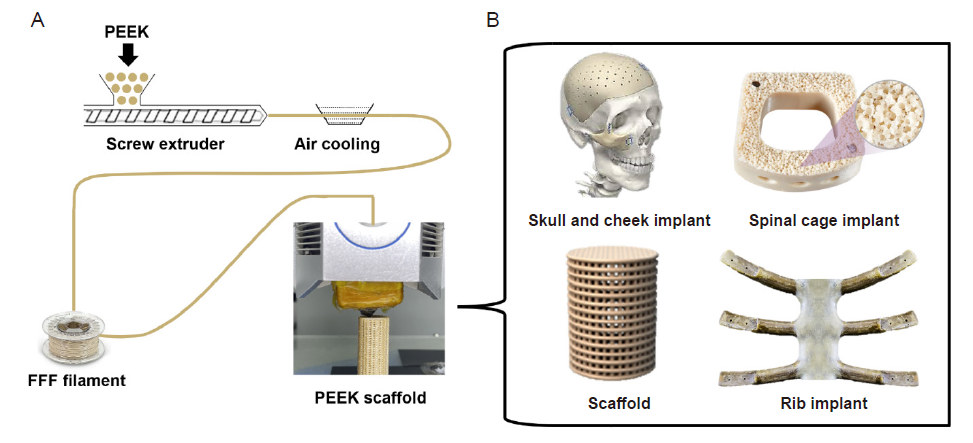

Figure 1. (A, B) Schematic illustration of the three-dimensional printing process of PEEK (A) and example application of PEEK material in biomedical field (B). FFF: fused filament fabrication; PEEK: polyether-ether-ketone.

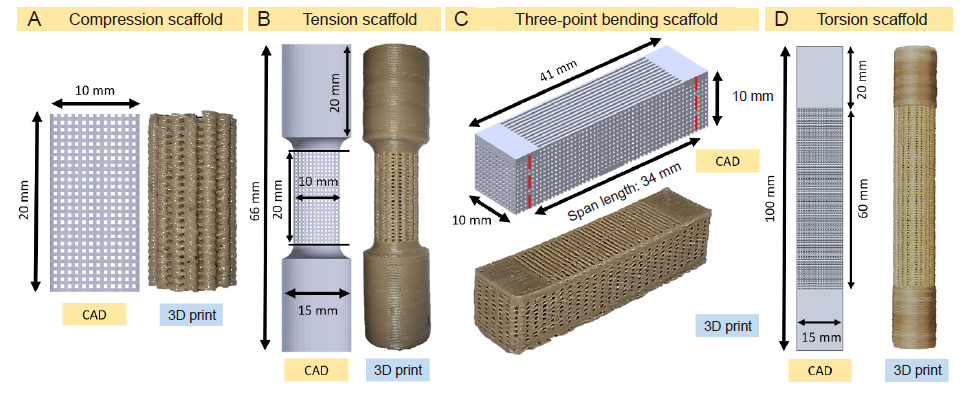

Figure 2. (A–D) Schematic CAD design and AM manufactured test specimens for compression (A), tension (B), three-point bending test (C), and torsion (D). 3D: three-dimensional; AM: additive manufacturing; CAD: computer-aided design.

| Parameter | Value |

|---|---|

| Nozzle temperature (°C) | 420 |

| Ambient temperature (°C) | 20 |

| Nozzle diameter (mm) | 0.4 |

| Printing speed (mm/s) | 20 |

| Layer thickness (mm) | 0.2 |

Table 1. The process parameters of three-dimensional printing

| Parameter | Value |

|---|---|

| Nozzle temperature (°C) | 420 |

| Ambient temperature (°C) | 20 |

| Nozzle diameter (mm) | 0.4 |

| Printing speed (mm/s) | 20 |

| Layer thickness (mm) | 0.2 |

| CAD | Micro-CT | % Error | |

|---|---|---|---|

| Porosity (%) | 50 | 61.05±0.86 | 22.1 |

| Strut thickness (mm) | 0.4 | 0.31±0.01 | 22.5 |

| Pore size (mm) | 0.4 | 0.46±0.03 | 15.0 |

| Surface to volume ratio (mm–1) | 7.56 | 8.08±0.24 | 6.9 |

Table 2. Comparison of morphological properties of CAD data and micro-CT data

| CAD | Micro-CT | % Error | |

|---|---|---|---|

| Porosity (%) | 50 | 61.05±0.86 | 22.1 |

| Strut thickness (mm) | 0.4 | 0.31±0.01 | 22.5 |

| Pore size (mm) | 0.4 | 0.46±0.03 | 15.0 |

| Surface to volume ratio (mm–1) | 7.56 | 8.08±0.24 | 6.9 |

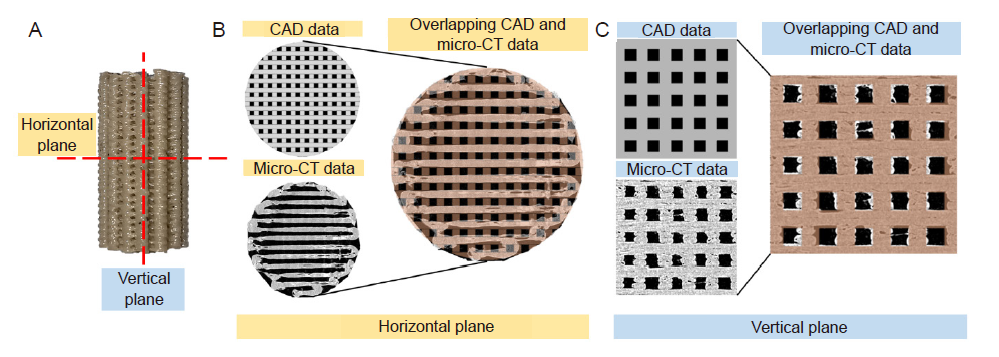

Figure 3. (A) Compression scaffold with defined horizontal and vertical planes (red dotted lines). (B, C) Overlapping CAD data and micro-CT data in horizontal (B) and vertical planes (C). CAD: computer aided design; micro-CT: micro-computed tomography.

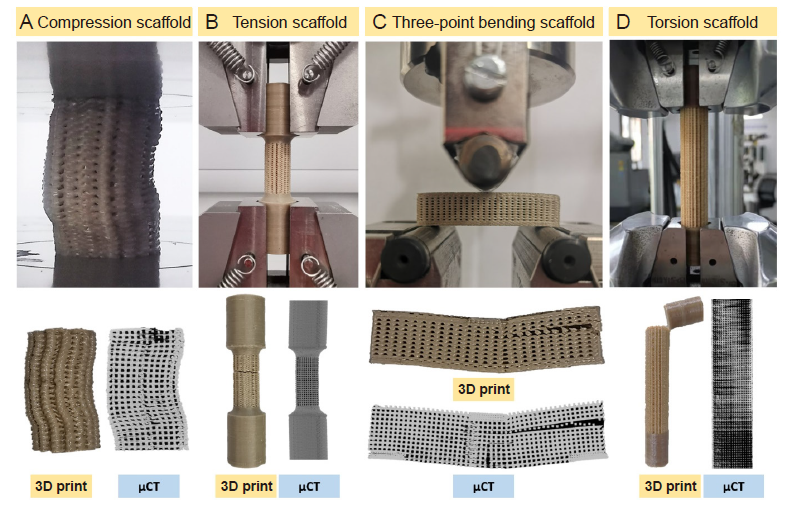

Figure 5. (A-D) Corresponding experimental mechanical testing images of compression (A), tension (B), three-point bending (C) and torsion (D) scaffolds. 3D: three-dimensional; μCT: micro-computed tomography.

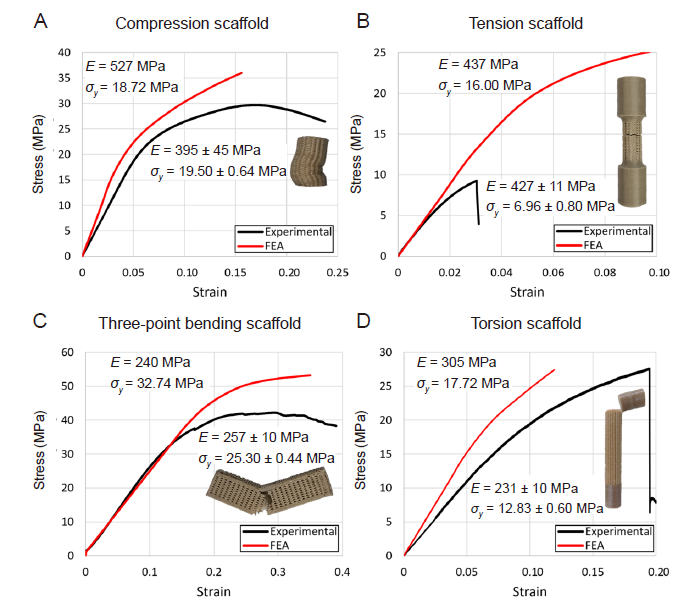

Figure 6. (A-D) Stress-strain curve of experimental and finite element model in compression (A), tension (B) and three-point bending (C), and torsion (D) scaffolds. E: Modulus; FEA: finite element analysis; G: shear modulus; σy: yield strength.

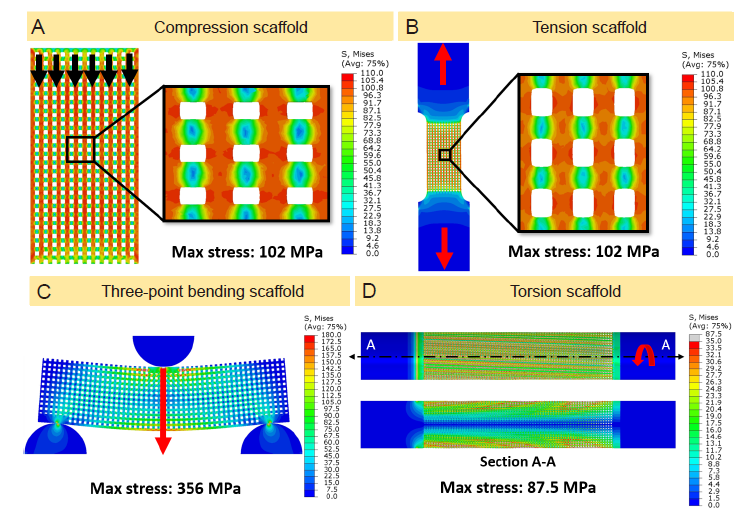

Figure 7. (A-D) Section view of finite element model results of compression (A) tension (B), three-point bending (C), and torsion (D) scaffolds. The red arrows show the direction of the applied load.

| Test | Young’s modulus (MPa) | Yield stress (MPa) | ||||

|---|---|---|---|---|---|---|

| Experimental | Simulation | % Error | Experimental | Simulation | % Error | |

| Compression | 395±45 | 527 | 25.1 | 19.50±0.64 | 18.72 | 4.2 |

| Tension | 427±11 | 437 | 2.4 | 6.96±0.80 | 16.00 | 56.5 |

| Three-point bending | 257±10 | 240 | 7.1 | 25.30±0.44 | 32.74 | 22.7 |

| Torsion | 231±10 | 305 | 24.4 | 12.83±0.60 | 17.72 | 27.6 |

Table 3. Comparison of mechanical properties obtained from the experimental data, finite element plasticity model from compression, tension, three-point bending and torsion testing

| Test | Young’s modulus (MPa) | Yield stress (MPa) | ||||

|---|---|---|---|---|---|---|

| Experimental | Simulation | % Error | Experimental | Simulation | % Error | |

| Compression | 395±45 | 527 | 25.1 | 19.50±0.64 | 18.72 | 4.2 |

| Tension | 427±11 | 437 | 2.4 | 6.96±0.80 | 16.00 | 56.5 |

| Three-point bending | 257±10 | 240 | 7.1 | 25.30±0.44 | 32.74 | 22.7 |

| Torsion | 231±10 | 305 | 24.4 | 12.83±0.60 | 17.72 | 27.6 |

| 1. |

Verma, S.; Sharma, N.; Kango, S.; Sharma, S. Developments of PEEK (Polyetheretherketone) as a biomedical material: a focused review. Eur Polym J. 2021, 147, 110295.

doi: 10.1016/j.eurpolymj.2021.110295 URL |

| 2. |

Yu, Y. H.; Liu, S. J. Polyetheretherketone for orthopedic applications: a review. Curr Opin Chem Eng. 2021, 32, 100687.

doi: 10.1016/j.coche.2021.100687 URL |

| 3. |

Gu, X.; Sun, X.; Sun, Y.; Wang, J.; Liu, Y.; Yu, K.; Wang, Y.; Zhou, Y. Bioinspired modifications of PEEK implants for bone tissue engineering. Front Bioeng Biotechnol. 2020, 8, 631616.

doi: 10.3389/fbioe.2020.631616 URL |

| 4. |

Zanjanijam, A. R.; Major, I.; Lyons, J. G.; Lafont, U.; Devine, D. M. Fused filament fabrication of PEEK: a review of process-structure-property relationships. Polymers. 2020, 12, 1665.

doi: 10.3390/polym12081665 URL |

| 5. |

Kurtz, S. M.; Devine, J. N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials. 2007, 28, 4845-4869.

doi: 10.1016/j.biomaterials.2007.07.013 URL |

| 6. |

Liu, C. Z.; Sachlos, E.; Wahl, D. A.; Han, Z. W.; Czernuszka, J. T. On the manufacturability of scaffold mould using a 3D printing technology. Rapid Prototyp J. 2007, 13, 163-174.

doi: 10.1108/13552540710750915 URL |

| 7. |

Alemán-Domínguez, M. E.; Giusto, E.; Ortega, Z.; Tamaddon, M.; Benítez, A. N.; Liu, C. Three-dimensional printed polycaprolactone-microcrystalline cellulose scaffolds. J Biomed Mater Res B Appl Biomater. 2019, 107, 521-528.

doi: 10.1002/jbm.b.34142 URL |

| 8. |

Kang, J.; Wang, L.; Yang, C.; Wang, L.; Yi, C.; He, J.; Li, D. Custom design and biomechanical analysis of 3D-printed PEEK rib prostheses. Biomech Model Mechanobiol. 2018, 17, 1083-1092.

doi: 10.1007/s10237-018-1015-x URL |

| 9. |

Wang, L.; Huang, L.; Li, X.; Zhong, D.; Li, D.; Cao, T.; Yang, S.; Yan, X.; Zhao, J.; He, J.; Cao, Y.; Wang, L. Three-dimensional printing PEEK implant: a novel choice for the reconstruction of chest wall defect. Ann Thorac Surg. 2019, 107, 921-928.

doi: 10.1016/j.athoracsur.2018.09.044 URL |

| 10. |

Kang, J.; Zhang, J.; Zheng, J.; Wang, L.; Li, D.; Liu, S. 3D-printed PEEK implant for mandibular defects repair - a new method. J Mech Behav Biomed Mater. 2021, 116, 104335.

doi: 10.1016/j.jmbbm.2021.104335 URL |

| 11. | Liu, D.; Fu, J.; Fan, H.; Li, D.; Dong, E.; Xiao, X.; Wang, L.; Guo, Z. Application of 3D-printed PEEK scapula prosthesis in the treatment of scapular benign fibrous histiocytoma:A case report. J Bone Oncol. 2018, 12, 78-82. |

| 12. | Sun, F.; Shen, X.; Zhou, N.; Gao, Y.; Guo, Y.; Yang, X.; Wu, G. A speech bulb prosthesis for a soft palate defect with a polyetherketoneketone (PEKK) framework fabricated by multiple digital techniques: a clinical report. J Prosthet Dent. 2020, 124, 495-499. |

| 13. |

Wu, C.; Zeng, B.; Deng, J.; Shen, D.; Wang, X.; Tan, L.; Liu, X.; Qiu, G. Custom design and biomechanical clinical trials of 3D-printed polyether ether ketone femoral shaft prosthesis. J Biomed Mater Res B Appl Biomater. 2022. doi: 10.1002/jbm.b.35055.

doi: 10.1002/jbm.b.35055 URL |

| 14. |

Najeeb, S.; Bds, Z. K.; Bds, S. Z.; Bds, M. S. Bioactivity and osseointegration of PEEK are inferior to those of titanium: a systematic review. J Oral Implantol. 2016, 42, 512-516.

doi: 10.1563/aaid-joi-D-16-00072 URL |

| 15. |

Walsh, W. R.; Pelletier, M. H.; Bertollo, N.; Christou, C.; Tan, C. Does PEEK/HA enhance bone formation compared with PEEK in a sheep cervical fusion model? Clin Orthop Relat Res. 2016, 474, 2364-2372.

doi: 10.1007/s11999-016-4994-x URL |

| 16. |

Zheng, J.; Zhao, H.; Ouyang, Z.; Zhou, X.; Kang, J.; Yang, C.; Sun, C.; Xiong, M.; Fu, M.; Jin, D.; Wang, L.; Li, D.; Li, Q. Additively-manufactured PEEK/HA porous scaffolds with excellent osteogenesis for bone tissue repairing. Compos B Eng. 2022, 232, 109508.

doi: 10.1016/j.compositesb.2021.109508 URL |

| 17. |

Zhu, Y.; Cao, Z.; Peng, Y.; Hu, L.; Guney, T.; Tang, B. Facile surface modification method for synergistically enhancing the biocompatibility and bioactivity of poly(ether ether ketone) that induced osteodifferentiation. ACS Appl Mater Interfaces. 2019, 11, 27503-27511.

doi: 10.1021/acsami.9b03030 URL |

| 18. |

Zheng, J.; Zhao, H.; Dong, E.; Kang, J.; Liu, C.; Sun, C.; Li, D.; Wang, L. Additively-manufactured PEEK/HA porous scaffolds with highly-controllable mechanical properties and excellent biocompatibility. Mater Sci Eng C Mater Biol Appl. 2021, 128, 112333.

doi: 10.1016/j.msec.2021.112333 URL |

| 19. |

Oladapo, B. I.; Ismail, S. O.; Adebiyi, A. V.; Omigbodun, F. T.; Olawumi, M. A.; Olawade, D. B. Nanostructural interface and strength of polymer composite scaffolds applied to intervertebral bone. Colloids Surf Physicochem Eng Aspects. 2021, 627, 127190.

doi: 10.1016/j.colsurfa.2021.127190 URL |

| 20. |

Zhong, G.; Vaezi, M.; Mei, X.; Liu, P.; Yang, S. Strategy for controlling the properties of bioactive poly-ether-ether-ketone/hydroxyapatite composites for bone tissue engineering scaffolds. ACS Omega. 2019, 4, 19238-19245.

doi: 10.1021/acsomega.9b02572 URL |

| 21. | Seo, J.; Gohn, A. M.; Dubin, O.; Takahashi, H.; Hasegawa, H.; Sato, R.; Rhoades, A. M.; Schaake, R. P.; Colby, R. H. Isothermal crystallization of poly(ether ether ketone) with different molecular weights over a wide temperature range. Polym Cryst. 2019, 2, e10055. |

| 22. | International Organization for Standardization. ISO 13314: 2011. Mechanical testing of metals — ductility testing — compression test for porous and cellular metals. |

| 23. | American National Standards Institute. ASTM E143-13. Standard test method for shear modulus at room temperature. |

| 24. |

Maskery, I.; Sturm, L.; Aremu, A. O.; Panesar, A.; Williams, C. B.; Tuck, C. J.; Wildman, R. D.; Ashcroft, I. A.; Hague, R. J. M. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer. 2018, 152, 62-71.

doi: 10.1016/j.polymer.2017.11.049 URL |

| 25. |

Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J Mater Process Technol. 2017, 248, 1-7.

doi: 10.1016/j.jmatprotec.2017.04.027 URL |

| 26. |

Carpenter, R. D.; Klosterhoff, B. S.; Torstrick, F. B.; Foley, K. T.; Burkus, J. K.; Lee, C. S. D.; Gall, K.; Guldberg, R. E.; Safranski, D. L. Effect of porous orthopaedic implant material and structure on load sharing with simulated bone ingrowth: A finite element analysis comparing titanium and PEEK. J Mech Behav Biomed Mater. 2018, 80, 68-76.

doi: 10.1016/j.jmbbm.2018.01.017 URL |

| 27. |

El Halabi, F; Rodriguez, J. F; Rebolledo, L; Hurtós, E; Doblaré, M Mechanical characterization and numerical simulation of polyether-ether-ketone (PEEK) cranial implants. J Mech Behav Biomed Mater. 2011, 4, 1819-1832.

doi: 10.1016/j.jmbbm.2011.05.039 URL |

| 28. |

Sun, C; Wang, L; Kang, J; Li, D; Jin, Z Biomechanical optimization of elastic modulus distribution in porous femoral stem for artificial hip joints. J Bionic Eng. 2018, 15, 693-702.

doi: 10.1007/s42235-018-0057-1 URL |

| 29. |

Jiang, Q; Zaïri, F; Fréderix, C; Yan, Z; Derrouiche, A; Qu, Z; Liu, X; Zaïri, F Biomechanical response of a novel intervertebral disc prosthesis using functionally graded polymers: A finite element study. J Mech Behav Biomed Mater. 2019, 94, 288-297.

doi: 10.1016/j.jmbbm.2019.02.021 URL |

| 30. |

Sola, A; Bellucci, D; Cannillo, V Functionally graded materials for orthopedic applications - an update on design and manufacturing. Biotechnol Adv. 2016, 34, 504-531.

doi: 10.1016/j.biotechadv.2015.12.013 URL |

| [1] | Changning Sun, Jianfeng Kang, Chuncheng Yang, Jibao Zheng, Yanwen Su, Enchun Dong, Yingjie Liu, Siqi Yao, Changquan Shi, Huanhao Pang, Jiankang He, Ling Wang, Chaozong Liu, Jianhua Peng, Liang Liu, Yong Jiang, Dichen Li. Additive manufactured polyether-ether-ketone implants for orthopaedic applications: a narrative review [J]. Biomaterials Translational, 2022, 3(2): 116-133. |

| [2] | Yu Lu, Subodh Deshmukh, Ian Jones, Yu-Lung Chiu. Biodegradable magnesium alloys for orthopaedic applications [J]. Biomaterials Translational, 2021, 2(3): 214-235. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||