Editorial

Chaozong Liu, Zhidao Xia

2022, 3(2): 99-101. doi:10.12336/biomatertransl.2022.02.002

Viewpoint

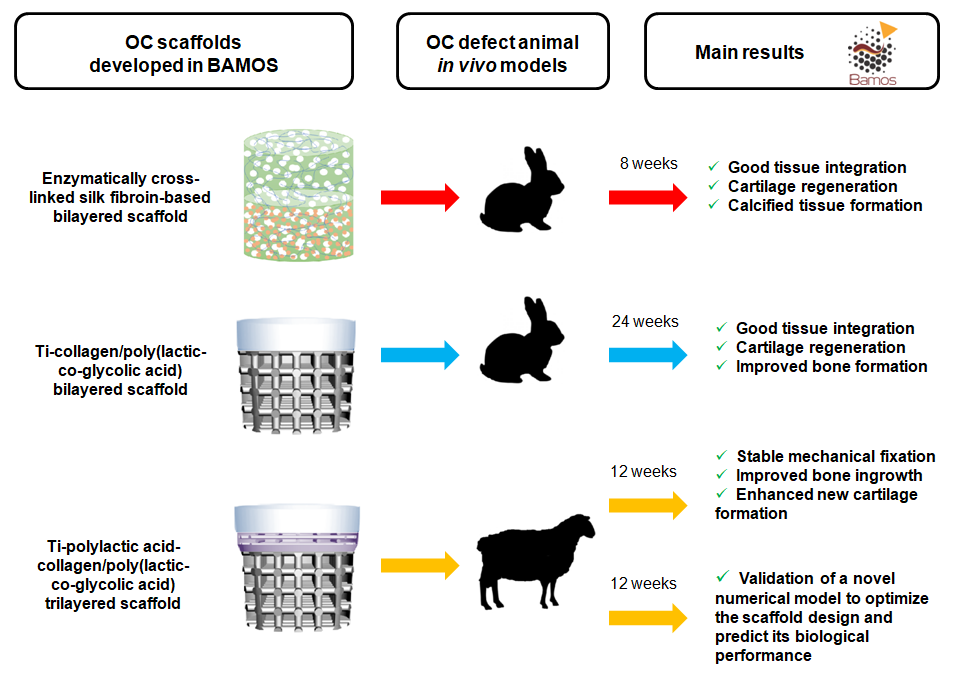

Ricardo Donate, Maryam Tamaddon, Viviana Ribeiro, Mario Monzón, J. Miguel Oliveira, Chaozong Liu

|

The main results of the in vivo evaluations carried out in Biomaterials and Additive Manufacturing: Osteochondral Scaffold (BAMOS) project, funded under Horizon 2020 Research and Innovation Staff Exchanges (RISE) program, are summarized. Animal models of osteochondral defect have been used to assess the biological performance of the different multi-material and multi-layered scaffolds developed. |

Reviews

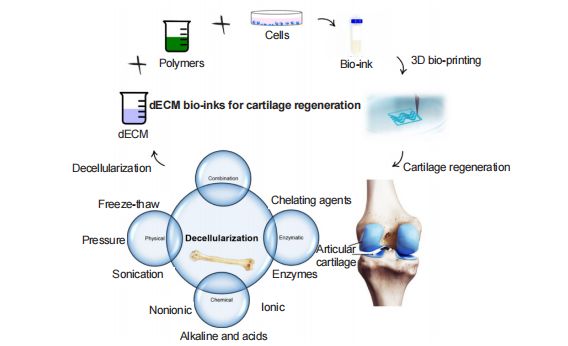

Melika Sahranavard, Soulmaz Sarkari, SeyedehMina Safavi, Farnaz Ghorbani

|

Decellularized extracellular matrix (dECM) can be used as a potential bio-ink for cartilage tissue engineering. This bioink can provide natural cues for cell adhesion and tissue regeneration. Here, the properties, sources, preparation process of dECM bio-inks, and previous studies on dECM bio-ink bio-printing for cartilage regeneration were reviewed. |

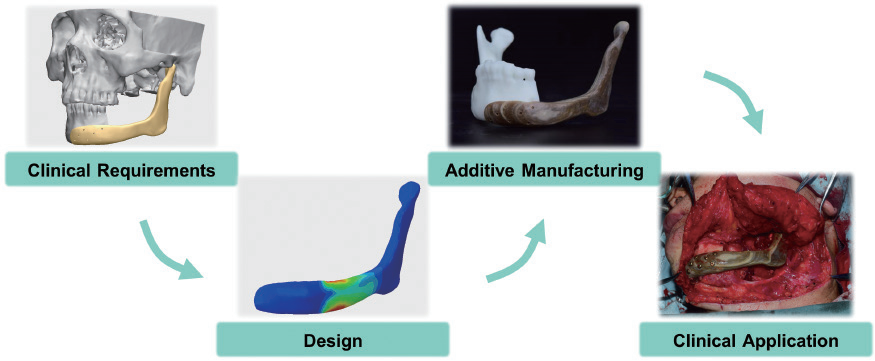

Changning Sun, Jianfeng Kang, Chuncheng Yang, Jibao Zheng, Yanwen Su, Enchun Dong, Yingjie Liu, Siqi Yao, Changquan Shi, Huanhao Pang, Jiankang He, Ling Wang, Chaozong Liu, Jianhua Peng, Liang Liu, Yong Jiang, Dichen Li

2022, 3(2): 116-133. doi:10.12336/biomatertransl.2022.02.001

|

Polyether-ether-ketone (PEEK) is a candidate material for the manufacture of next-generation orthopaedic implants. Customised PEEK implants have been used in clinical applications with the development of additive manufacturing. The design, manufacturing, evaluation and typical applications of PEEK customised implants are comprehensively reviewed. |

Research Articles

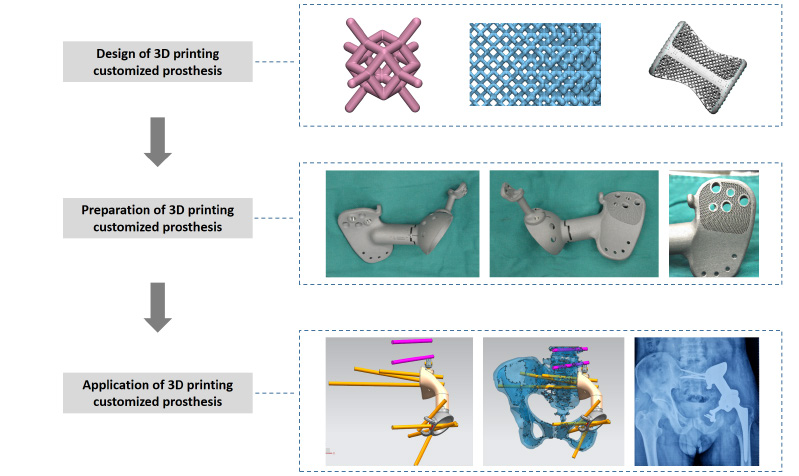

Feifei Pu, Wei Wu, Doudou Jing, Yihan Yu, Yizhong Peng, Jianxiang Liu, Qiang Wu, Baichuan Wang, Zhicai Zhang, Zengwu Shao

2022, 3(2): 134-141. doi:10.12336/biomatertransl.2022.02.005

|

Three-dimensional (3D)-printed prostheses with an individualised design can achieve satisfactory short-term clinical efficacy in the reconstruction of large bone defects after bone tumour resection. Using this method it is possible to print complex structures that are difficult to fabricate using traditional processes, and overcome the problems of stress shielding and low biological activity of conventional prostheses. |

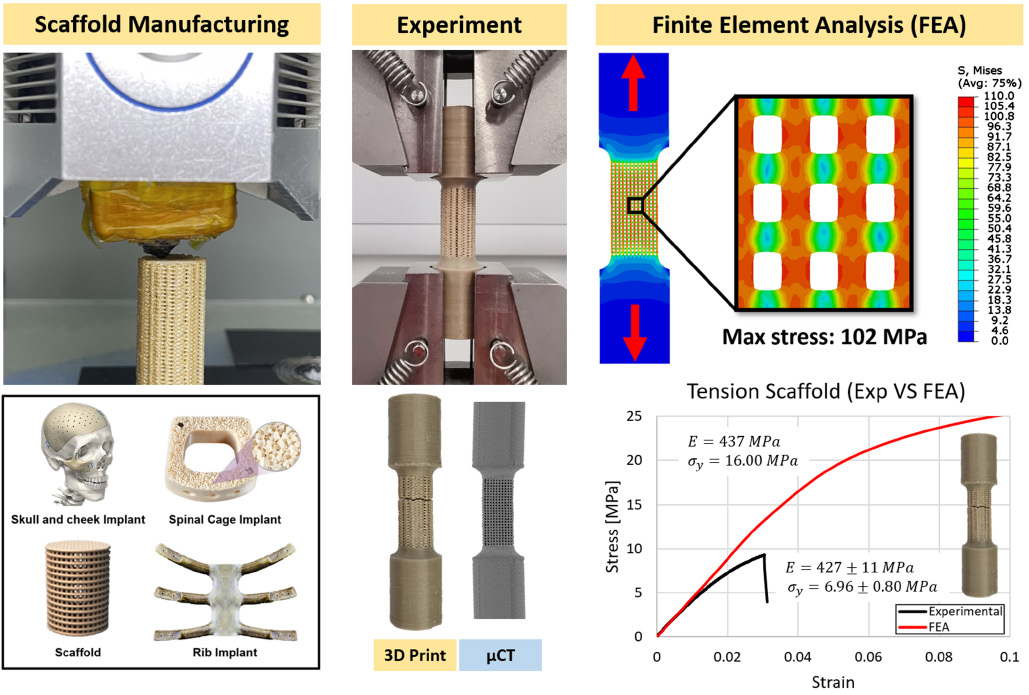

Seyed Ataollah Naghavi, Changning Sun, Mahbubeh Hejazi, Maryam Tamaddon, Jibao Zheng, Leilei Wang, Chenrui Zhang, Swastina Nath Varma, Dichen Li, Mehran Moazen, Ling Wang, Chaozong Liu

2022, 3(2): 142-151. doi:10.12336/biomatertransl.2022.02.006

|

Polyether-ether-ketone is an excellent biomaterial that has potential in orthopaedic applications. Additive Manufacturing has been widely used in fabrication of customer-tailored implants such as skull, spinal cage, rib cage, and scaffold for large bone defect reconstructions. The achieved mechanical performance of the implants is a key factor for translation of additive manufacturing. In this study, the compression, tension, three-point bending and torsion specimens were designed and additive manufacturing manufactured. The mechanical properties were tested and compared with the computational results. |

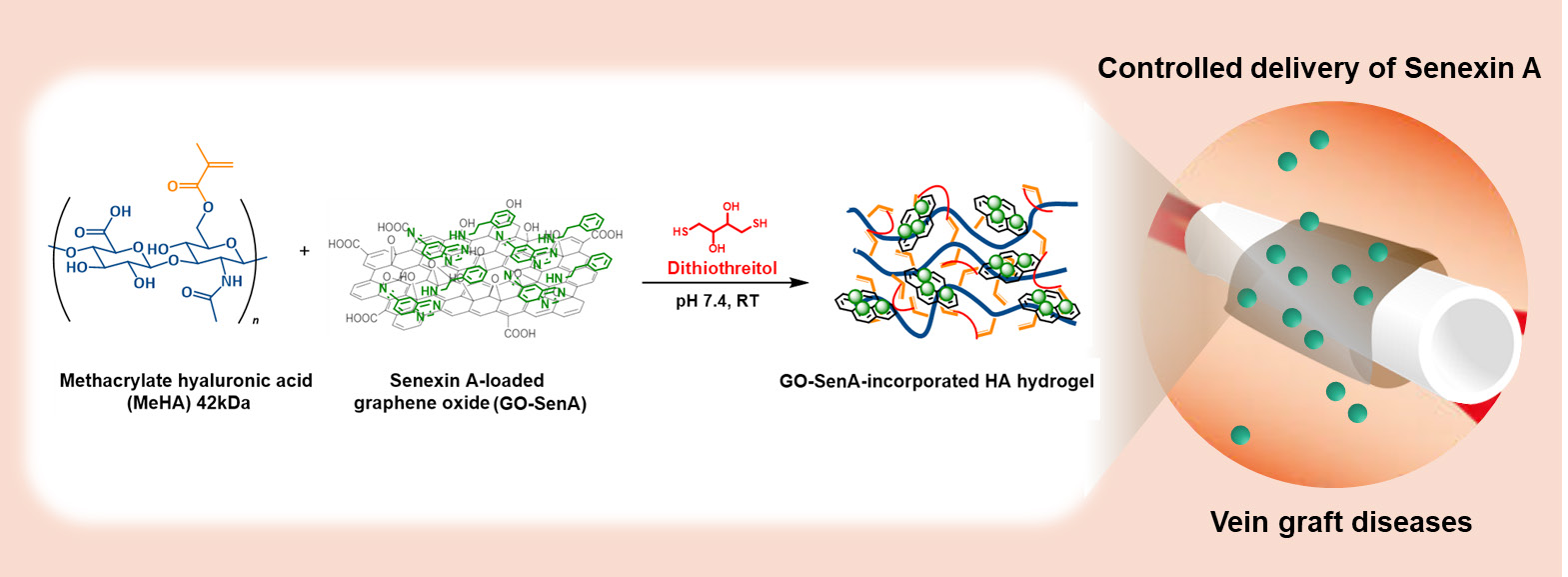

Graphene-incorporated hyaluronic acid-based hydrogel as a controlled Senexin A delivery system

Panita Maturavongsadit, Weiwei Wu, Jingyu Fan, Igor B. Roninson, Taixing Cui, Qian Wang

2022, 3(2): 152-161. doi:10.12336/biomatertransl.2022.02.007

|

This study demonstrates a novel biodegradable graphene-incorporated hyaluronic acid-based hydrogel that can effectively accommodate and deliver the cyclin-dependent kinase 8/19 inhibitor Senexin A to the adventitia of vessel grafts without any observed toxicity in vitro. The versatility of this hydrogel system supports its potential translation as a perivascular drug delivery system for treating occlusive vascular diseases. |

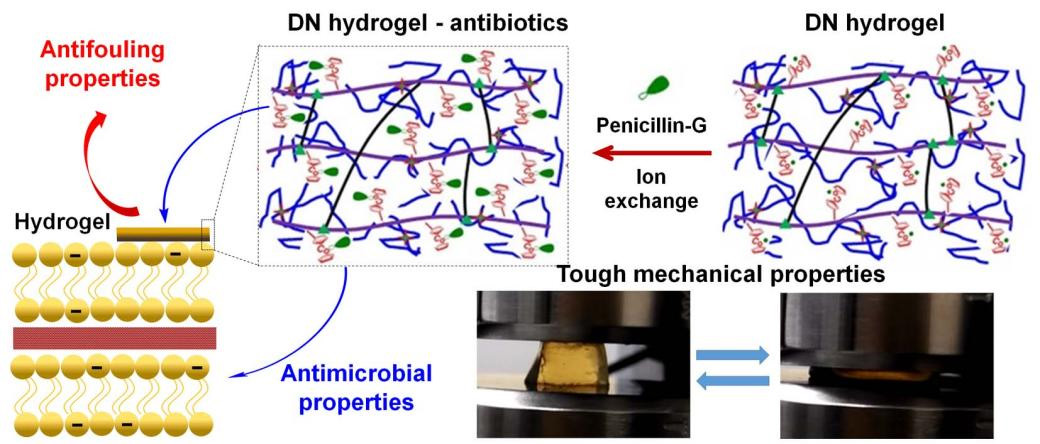

Antifouling and antimicrobial cobaltocenium-containing metallopolymer double-network hydrogels

Hui Li, Peng Yang, JiHyeon Hwang, Parasmani Pageni, Alan W. Decho, Chuanbing Tang

2022, 3(2): 162-171. doi:10.12336/biomatertransl.2022.02.008

|

Metallopolymer double-network (DN) hydrogels, composed of a first network of cationic cobaltocenium polyelectrolytes and a second network of polyacrylamide, are fabricated via two-step free radical polymerization. After installation with antibiotics, the hydrogel conjugates show remarkable mechanical ability, antifouling and antimicrobial properties. |